Anyone who manufactures CFRP components knows the task: a clamping fixture is usually required to trim the component to the actual contour. The same applies to thermoforming or coated parts (interiors). The requirements for the fixtures are high: the component must be held securely and allow clean trimming, waste pieces must not disturb the process.

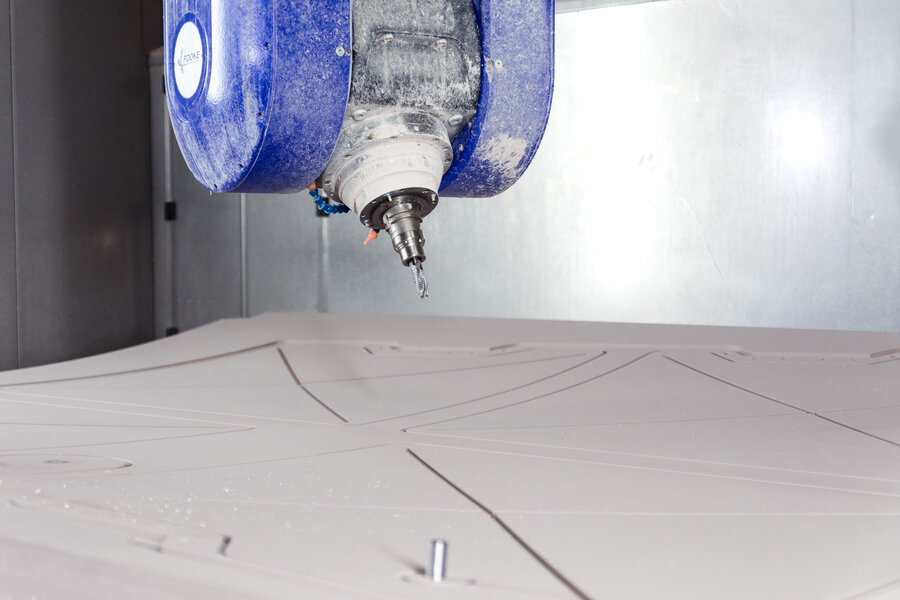

The production of the fixture is a "secondary activity". A necessary evil, so to speak, which wants to be done quickly in order to start earning money. With the ENDURA® 700 series, we offer a machine with the greatest flexibility and a wide range of applications. Not only the trimming, but also the necessary production of the operating materials can be done efficiently.

In the case of our practical example, a CFRP wing shell measuring approx. 2000 x 2500 mm, there was a further challenge: no more CAD data was available. So the wing had to be scanned first and the surfaces fed back.

In this webinar, you will learn how to design a vacuum clamping fixture from Ureol and link it parametrically to the part data. We will then show how the fixture is manufactured quickly and safely on a highly dynamic ENDURA® portal milling machine and with the appropriate tools as well as with the associated digital twins.

Click here for the online webinar part 1.

More info on milling also on Youtube.

An event by:

HUFSCHMIED Machining Systems GmbH

Tebis Technical Information Systems AG

FOOKE GmbH