Market leader in the machining of aluminum profiles for rail technology.

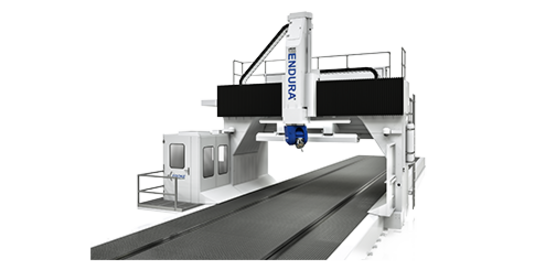

Travelling Column ENDURA® 1006LINEAR with 2 portals for the machining of large-volume aluminum profiles.

SIDE WALLS, ROOF AND FLOOR ASSEMBLIES

Travelling Column ENDURA® 1006LINEAR

- Work area division for 3-place machining

- Individual clamping concepts and fixtures on customer request

- up to 90m X-travel

- travelling operator cabin for better process monitoring

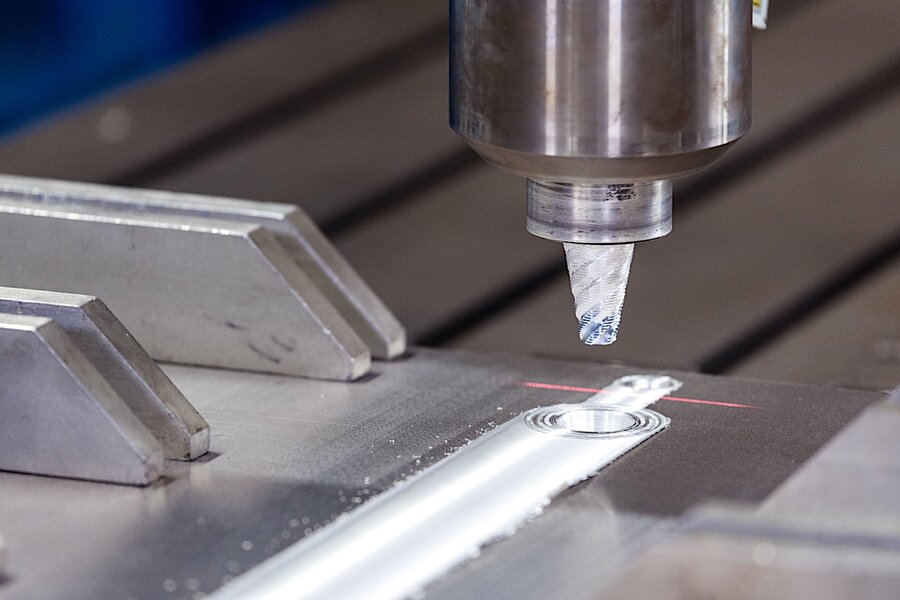

Customized clamping technology

for rail applications

Specialist for stringer and profil machining

Highly dynamic 5-axis machining of long workpieces with our long bed profile milling machine ENDURA® PRO LINEAR

- Encapsulated machining area

- Flexible workpiece clamping systems

- Rapid traverse 65,000 mm/min.

- Up to 60m X-travel

FOOKE FRICTION STIR WELDING - Strong joints for the industry

Shorter processing times and fully automatic process monitoring with FSW systems from FOOKE

FOOKE TURNKEY-solutions for the rail industry

PROCESS CONSULTING AND DEVELOPMENT

Machining strategies | machining and measuring programs

TECHNOLOGY - MACHINE CONCEPT (MILLING, FRICTION STIR WELDING, WATER JET CUTTING)

Customized design according to requirements | Optimized machine design | Tool selection| Chips and dust extraction systems

MEASUREMENT

Detection of component deviations, component positions

CLAMPING TECHNOLOGY

Individual clamping concepts | Flexible clamping systems | Partial or full automation

DEMONSTRATION CENTER

Preliminary tests and evaluation | Tests | Preliminary tests

PROCESS INTEGRATION AND MONITORING

Process introduction and monitoring | Data documentation for quality assurance purposes

HALL MANAGEMENT

Foundation design | Air management | Sound insulation |

INDIVIDUAL CLAMPING SYSTEMS

Secure your process with the highest quality

FOOKE FRICTION STIR WELDING

High machine stiffness - low compliance - stable FSW process - high weld seam quality - high process reliability

FOOKE FRICTION STIR WELDING

5-axis simultaneous welding with maximum axial force of 60 KN

FLEXIBLE CLAMPING FIXTURE

Fully automatic positioning

FOOKE FRICTION STIR WELDING

Stable FSW process -> high weld seam quality

Force control / distance control / seam tracking / gap monitoring

Railway

Make way for productivity

They need to be big, fast, reliable and, above all, robust: Milling systems for the manufacture of rail vehicles.

Many modern high-speed trains and trams are now manufactured worldwide from large-volume aluminum profiles and components. For this purpose, FOOKE developed milling systems and turnkey production centers in close cooperation with various customers as early as the 1990s.

As a reliable partner to our customers, we have of course consistently adapted our machines to meet the ever-increasing demands. For this reason, we are the global market leader in this segment.

In addition, friction stir welding systems (Friction-Stir Welding), welding and joining fixtures, assembly and erection stands round off our product portfolio for this industry.

Reliable, modern, economical.

What makes us proud

Some of our references in the rail industry

ALSTOM │ AMM MANUFACTURING │ BOMBARDIER │ HAI HAMMERER ALUMINIUM INDUSTRIES │ SIEMENS MOBILITY │ STADLER │ ST EXTRUDED PRODUCTS (STEP G) │ …

FOOKE Product range

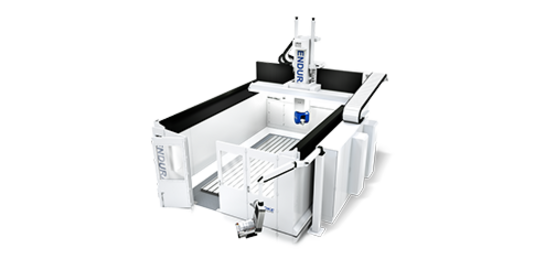

Compact Gantry Milling Machine

ENDURA® 400LINEAR

- NEW - highly efficient for plastics processing

- Large machining area, small installation surface, can be set up without foundations

- Direct drive motors in all axes (linear and torque motors)

- High structural rigidity, highest dynamics and best accuracies

- Easy transport and short commissioning due to compact machine design

- Consistently high precision due to temperature stability of the machine structure

- Travels up to 2,700 x 3,000 x 1,200 mm

- Range of materials: plastics, CFRP/GFRP, modeling block material, aluminum

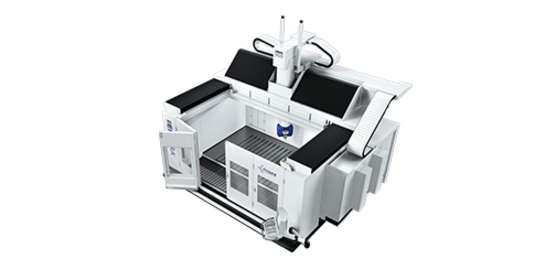

Gantry Milling Machine

ENDURA® 600LINEAR

- Very spacious machining area

- Loading at ground level

- Optimal dust extraction and chip conveyor concepts

- Direct drives in all axes (linear and torque motors)

- Entry model for 1:1 processing in vehicle design

- Individual concepts for highest accuracies of large-scale components in aviation

- Excellent productivity in the machining of multi-purpose large workpieces

- Customized solutions for clamping technology and suction systems

- Individual axis length configuration

- Travels up to 30,000 x 3,500 x 2,300 mm

- Range of materials: plastic, CFRP/GFRP, model building block material, aluminum

Compact Gantry Milling Machine

ENDURA® 700LINEAR

- Our bestseller! Proven since 2004, continuously optimized

- Large machining area, small installation surface, can be set up without foundations

- Direct drive motors in all axes (linear and torque motors)

- High structural rigidity, highest dynamics and best accuracies

- Easy transport and short commissioning due to compact machine design

- Consistently high precision due to temperature stability of the machine structure

- 5-sided machining of all common automotive components

- Highly efficient productivity in the machining of aluminum components

- Modular design allows extension of X travel as XL version

- Thermal decoupling of short-term temperature fluctuations by Thermo Guard

- Travels up to 5,500 x 3,500 x 1,500 mm

- Range of materials: plastics, CFRP/GFRP, modeling block material, aluminum, cast iron, steel

Compact Gantry Milling Machine

ENDURA® 7000LINEAR

- For high-performance heavy-duty machining of high-strength materials

- Large machining area, small footprint, foundationless installation

- Thermosymmetrical machine concept

- High structural rigidity, highest dynamics and outstanding accuracies

- Material range: steel, cast iron and aluminum

- Direct drives in all axes (linear and torque motors)

- Travels up to 6,000 x 4,500 x 1,500 mm

- Range of materials: steel, cast iron and aluminum

Ganty Milling Machine

ENDURA® 900LINEAR

- Highly dynamic, for universal applications

- Direct drives in all axes (linear and torque motors)

- Excellent structural rigidity, highest dynamics and accuracies

- Very large enveloped machining area

- Market leader in 1:1 machining in German automotive design

- Perfectly matched machine concept for productive end-to-end machining from aluminum to steel

- Now also available in compact design

- Travels up to 30,000 x 4,500 x 3,000 mm

- Range of materials: plastic, CFRP/GFRP, modeling block material, aluminum, cast iron, steel

Compact Gantry Milling Machine

ENDURA® 900LINEAR

- Large machining area, small installation surface, can be set up without foundation

- Direct drive motors in all axes (linear and torque motors)

- High structural rigidity, highest dynamics and accuracies

- Thermal decoupling of short-term temperature fluctuations by Thermo Guard

- Travels up to 5,500 x 3,500 x 1,500 mm

- Range of materials: steel, cast iron and aluminum

Longbed Profile Milling Machine

ENDURA® PRO LINEAR

- Specialist for stringer and profil machining

- Highly dynamic 5-axis machining of long workpieces

- Material removal rates up to 11.0 l/min

- Flexible workpiece clamping systems

- Ergonomic loading

- Two-station component machining for process-parallel loading

- Monobloc machine bed design, modularly expandable

- Encapsulated machining area by bullet-proof lamellas

- Travels up to 60,000 x 3,100 x 1,500 mm

- Range of materials: aluminum, composites (CFRP/GFRP)

Travelling Column MIlling Machine

ENDURA® 1000LINEAR

- Specialist or large volume workpieces

- Ergonomic loading

- Travelling operator cabin for optimal process monitoring

- Traveling tool changer

- Market leader in the machining of aluminum profiles for the rail technology

- Individual clamping concepts and fixtures on customer request

- Available with mechanical drive components or modern linear motor drives

- Three-station component machining for process-parallel loading and unloading

- FSW retrofit solution for friction stir welding with max. axial force of 25 kN

- Travels up to 60,000 x 4,500 x 2,100 mm

- Range of materials: plastic, CFRP/GFRP, aluminum, cast iron, steel

Plate Milling Machine

ENDURA® 800

- Face milling machine for large aluminum precision plates

- Highest accuracies due to extremely rigid machine structure

- Finish operation in one milling process

- Ergonomic loading

- Surface quality < 0.4 µm

- Milling tool up to Ø 3,100 mm

Do you have questions about our products

Our sales team is at your service

Feel free to mail us or call us. We look forward to your questions and suggestions. You will receive an answer as soon as possible.

Tel.: +49 (0) 2861 / 8009 - 222

E-Mail: sales@fooke.de