Compact Milling Machine

Compact linear motor milling machine with 5 CNC-controlled simultaneous axes, ideal for the efficient machining of workpieces made of aluminium, cast iron and steel in 5-sided production.

Advantages at a glance.

- Large machining area, small installation surface, can be set up without foundation

- Direct drive motors in all axes (linear and torque motors)

- High structural rigidity, highest dynamics and accuracies

- Thermal decoupling of short-term temperature fluctuations by Thermo Guard

- Travels up to 9,000 x 3,500 x 1,500 mm

- Range of materials: steel, cast iron and aluminum

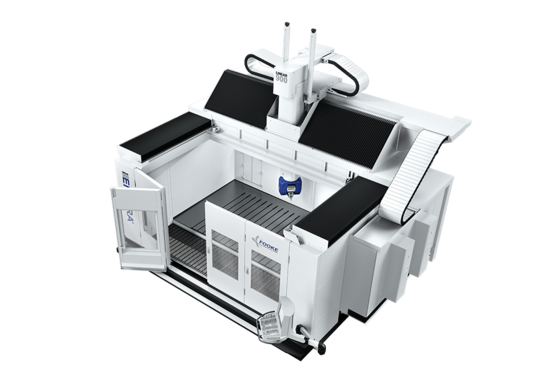

Gantry Milling Machine

ENDURA® 900LINEAR Compact

Compact gantry milling machine with large machining area and small footprint.

Traverse paths

X-axis: 2,500 / 4,000 / 5,500 mm

Y-axis: 3,500 mm

Z-axis: 1,500 mm

Feed rates

X-axis: 5 - 65,000 mm/min

Y-axis: 5 - 65,000 mm/min

Z-axis: 5 - 65,000 mm/min

Acceleration up to 5 m/sec²

Position accuracy

X-axis: 0.015 mm

Y-axis: 0.015 mm

Z-axis: 0.015 mm

Position scatter

X-axis: 0.010 mm

Y-axis: 0.010 mm

Z-axis: 0.010 mm

Inherently rigid compact machine with closed machine bed

Wear-free, highly dynamic linear motors in all linear axes (X, Y and Z)

Direct measuring systems in all axes (X, Y, Z, C and A)

Safety systems and brakes in all linear axes (X, Y and Z)

Drive units consistently protected by bellows

Automatic tool changing systems

Minimum quantity spray dosing system

Coolant systems (wet operation)

Tool measuring systems

Workpiece measuring systems

Chips and dust disposal systems

Plane cover / Sound insulation enclosure

Online-Service

Highly dynamic by the use of linear motors

Rigid machine system - highly damping structural elements

Features, technology and equipment:

- Highly dynamic overhead GANTRY tool milling machine in compact design:

Gantry moving in X-direction. - Design of the machine:

Machine bed made of solid cast iron, side walls (X-axis), cross slide, walking beam (Z-axis) and portal

(Y-axis) as extremely rigid, yet weight-optimized welded steel construction. - No foundation necessary:

Due to the inherently rigid machine bed, a standard industrial floor, approx. 300 mm thick, steel-reinforced, is sufficient for the installation; a special foundation, is not required. The machine is set up and aligned by fixators bolted to the hall floor. - Drive technology of linear axes:

Water-cooled linear motors in the linear axes (X, Y and Z), X axis designed as a GANTRY axes pair.

- Direct measuring systems:

The linear and rotary axes are equipped with direct measuring systems. - Z-axis weight compensation:

Highly dynamic pneumatic cylinders support the Z-axis drive. - Direct measuring systems:

The linear and rotary axes are equipped with direct measuring systems. - Linear axes guides:

The linear axes are equipped with hardened and ground, backlash-free pre-tensioned guide elements. - Thermal decoupling:

Coating and cladding of relevant structural components with suitable insulation material and sheet metal. Negative influences of external temperature fluctuations on the positioning accuracy of the machine are significantly reduced through thermal decoupling.

Download Product Brochure

Download Milling Head Overview