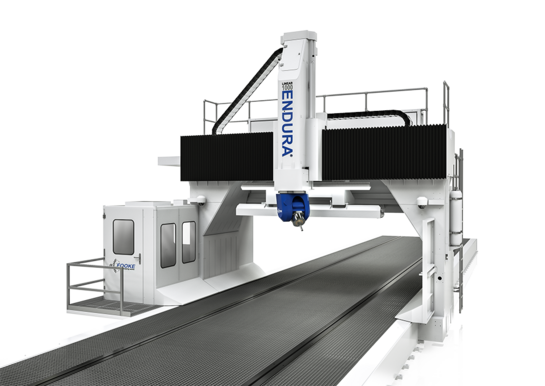

Longbed Milling Machine

Our specialist for large-volume workpieces - ergonomic loading.

The linear motor drive technology has already impressively proven itself in many machines from FOOKE GmbH's product range. Therefore, the linear motor drive technology was again used in the long bed milling machine ENDURA® 1000LINEAR. The machine concept of the FOOKE ENDURA® tool milling machine is particularly suitable for high-speed machining of large-volume workpieces.

The easy loadability of an ENDURA® 1000LINEAR long bed milling machine, even with the largest workpieces, is also an enormous advantage of this machine concept. Due to its design, this long bed milling machine can be manufactured in almost any length (X travel).

Modular long bed milling machine with high acceleration rates: Acceleration rates of up to 5 m/sec² impressively reflect the dynamics and precision of these machines. With the same surface quality and accuracy, you can achieve a significant increase in speed compared to conventional long bed milling machines.

Advantages at a glance.

- Specialist or large volume workpieces

- Ergonomic loading

- Travelling operator cabin for optimal process monitoring

- Traveling tool changer

- Market leader in the machining of aluminum profiles for the rail technology

- Individual clamping concepts and fixtures on customer request S

- Available with mechanical drive components or modern linear motor drives

- Three-station component machining for process-parallel loading and unloading

- FSW retrofit solution for friction stir welding with max. axial force of 25 kN

- Travels up to 90,000 x 5,000 x 2,000 mm

- Range of materials: plastic, CFRP/GFRP, aluminum, cast iron, steel

Long Bed Milling Machine

ENDURA 1000LINEAR

Milling machine for the processing of large-volume workpieces.

Traverse paths

X-axis: 5,000 - 60,000 mm

Y-axis: 4,500 mm

Z-axis: 1,600 / 1,900 / 2,100 mm

Feed rates

X-axis: 5 - 55,000 mm/min

Y-axis: 5 - 65,000 mm/min

Z-axis: 5 - 65,000 mm/min

Accleration up to 5 m/sec²

Repeatability

X-axis: +/- 0.015 mm

Y-axis: +/- 0.015 mm

Z-axis: +/- 0.015 mm

Position accuracy

X-axis: +/- 0.080 mm

Y-axis: +/- 0.030 mm

Z-axis: +/- 0.025 mm

Modular and extremely rigid machine with an intelligent hybrid design (steel, welded, cast iron and mineral casting components).

Resistant, highly powerful linear motors in the linear axes (Y and Z).

Direct measuring systems in all axes (X, Y, Z, C and A).

Safety system and brakes in all linear axes (X, Y and Z).

Linear guiding devices and drive motors are efficiently protected by bellows.

Easily accessible ground-level machine room for crane or forklift truck loading and unloading.

Automatic tool change systems

Cooling systems (wet operation)

Two-station component machining for process-parallel loading and unloading

Tool measuring systems

Workpiece measuring systems

Chips and dust disposal systems

Workpiece clamping systems

Sound insulation enclosure

Online service

Specialist for large volume workpieces

Individual clamping concepts and fixtures according to customer requirements

Features, technology and equipment:

- Highly modern GANTRY portal milling machine:

Gantry moving in X-direction. - Design of the machine:

The machine bed with the laterally mounted X-guide and drive systems of the gantry is built and aligned on the foundation designed for this purpose. The longitudinal beams of the machine bed are braced by cross beams. The moving column, longitudinal beams, cross beams, portal (Y-axis) and walking beam (Z-axis) are each manufactured as a rigid welded steel structure. - Drive technology of linear axes:

Water-cooled linear motors in linear axes Y and Z, X-axis designed as rack-and-pinion GANTRY unit and drive motors in MASTER-SLAVE arrangement.

- Measuring systems:

The X axis is equipped with an indirect measuring system and the Y, Z and rotary axes are equipped with direct measuring systems. - Z-axis weight compensation:

Highly dynamic pneumatic cylinders support the Z-axis drive. - Safety system of linear axes:

The linear axes are equipped with a safety system that can decelerate and hold the axes safely in the event of a loss of voltage. - Linear axes guides:

The linear axes are equipped with hardened and ground, backlash-free pre-tensioned guide elements.

Download Product Brochure

Download Milling Head Overview