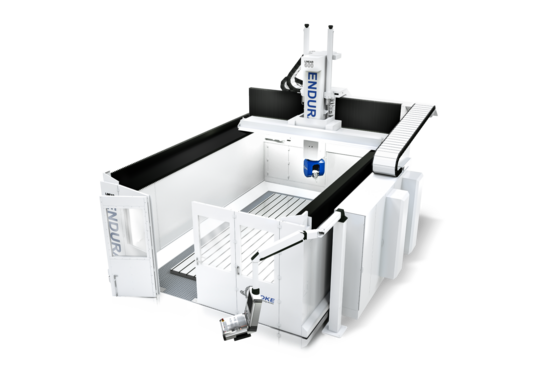

Gantry Milling Machine

for high-speed machining of large workpieces.

State-of-the-art linear drives gantry milling machine in portal design with 5 CNC-controlled simultaneous axes, particularly suitable for the efficient 5-sided finishing of workpieces made of clay, plastic, composite materials (CFRP, GFRP), model building block material (Ureol)

and the HSC machining of aluminum. The ENDURA® 600LINEAR gantry milling machine is equipped with linear motor drive technology, which has especially established for high-speed machining of large workpieces. Acceleration values of up to 9.8" /sec²

classify this series in the category of high-speed milling machines. 5-axis machining of workpieces with maximum dimensions of 95" x 9.2" x 5.2".

Advantages at a glance.

- Large machining area

- x= 197” to 1,180”, y= 110”/138”, z= 60”/80”

- Feed rates: 2,560 ipm

- Linear motors in x, y, z axis

- Torque motors in C & A axis

- Fully enclosed w/folding covers

- Direct measuring systems in all axes (X, Y, Z, C and A).

- Suitable Milling heads: #4 and #11

- Perfect for plastics, CFRP/GFRP, block material, aluminum and steel

- ATC w/68+ tools

- Tool measurement probe

- Part measurement probe

- Vibration sensing system

Gantry milling machine

ENDURA 600LINEAR

Highly dynamic gantry milling machine for universal applications.

Traverse paths

X-axis: 196.9" - 1,181.1"

Y-axis: 110.2" / 137.8"

Z-axis: 59.1" / 78.7" / 90.6"

Feed rate

X-axis: 0.197"/min - 2,559.1"/min

Y-axis: 0.197"/min - 2,559.1"/min

Z-axis: 0.197"/min - 2,559.1"/min

Acceleration up to 118.1"/sec²

Positioning accuracy

in X (P) 0.0011"

in Y (P) 0.0007"

in Z (P) 0.0006"

Positioning scatter band

in X (Ps Average ) 0.0006"

in Y (Ps Average ) 0.0004"

in Z (Ps Average ) 0.0004"

Wear-free, highly dynamic linear motors in all linear axes (X, Y and Z) and torque motors in the rotary axes (C and A).

Direct measuring systems in all axis (X, Y, Z, C and A).

Safety systems and brakes in all linear axis.

Drive units consistently protected by bellows.

Extremely fast and dynamic milling machine with overhead gantry travelling in X-direction.

Machine room accessible at ground level, can be loaded and unloaded by crane or forklift.

Automatic tool changing systems

Minimum quantity spray dosing system

Coolant systems (wet operation)

Tool measuring systems

Workpiece measuring systems

Chips and dust disposal systems

Plane cover / Sound insulation enclosure

Online-Service

Highly dynamic by the use of linear drives

Rigid machine system - highly damping structural elements

Features, technology and equipment:

- Highly dynamic portal milling machine in overhead GANTRY design:

Overhead travelling portal in X-direction. - Design of the Machine:

Side walls (X-axis), cross slide, portal (Y-axis) and walking beam (Z-axis) are designed as a solid, stress-relief annealed welded steel structure. - Drive technology of linear axes

Water-cooled linear motors in the linear axes (X, Y and Z), X-axis configured as GANTRY-axis pair.

- Direct measuring systems:

The linear and rotary axes are equipped with direct measuring systems. - Z-axis weight compensation:

Highly dynamic pneumatic cylinders support the Z-axis drive. - Safety system of linear axes:

The linear axes are equipped with a safety system that can decelerate and hold the axes safely in the event of a loss of voltage. - Linear axes guides:

The linear axes are equipped with hardened and ground, backlash-free pre-tensioned guide elements.

Download Product Brochure

Download Milling Head Overview