50% WEIGHT REDUCTION

OF 10 x 2 m FUSELAGE

the traditional method of chemical miling in the aerospace industry is superseded by FOOKE`s turnkey solution.

HIGHLY EFFICIENT MACHINING OF WING FLAPS MADE OF CFRP .

GKN and FOOKE

"FOOKE has highly qualified specialists who develop very economical solutions and implement them punctually and accurately. I rarely experience anything like this".

Hans-Jochen Platte, Production Manager

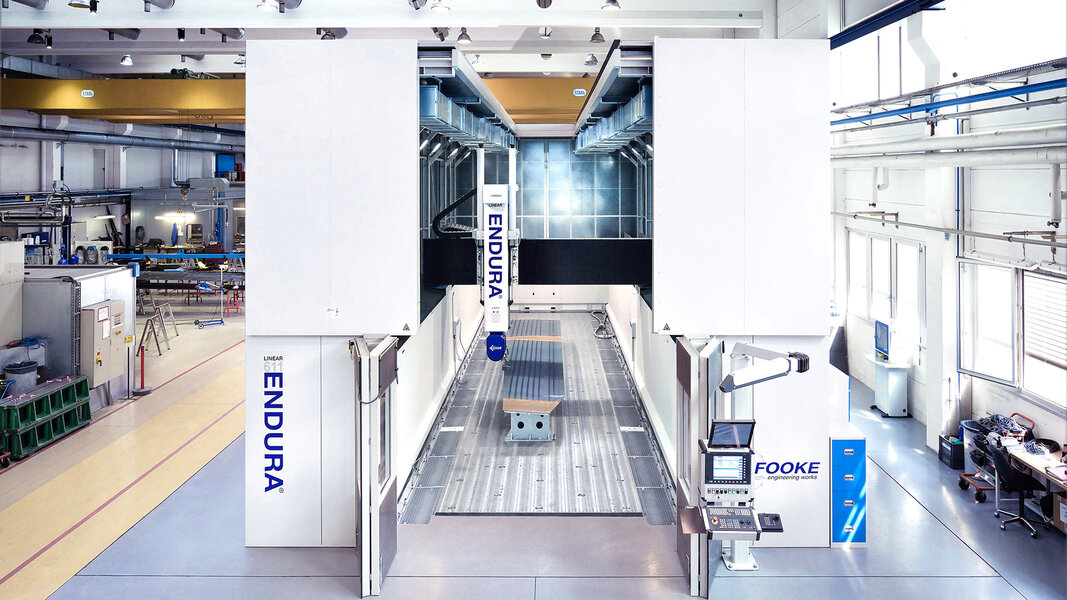

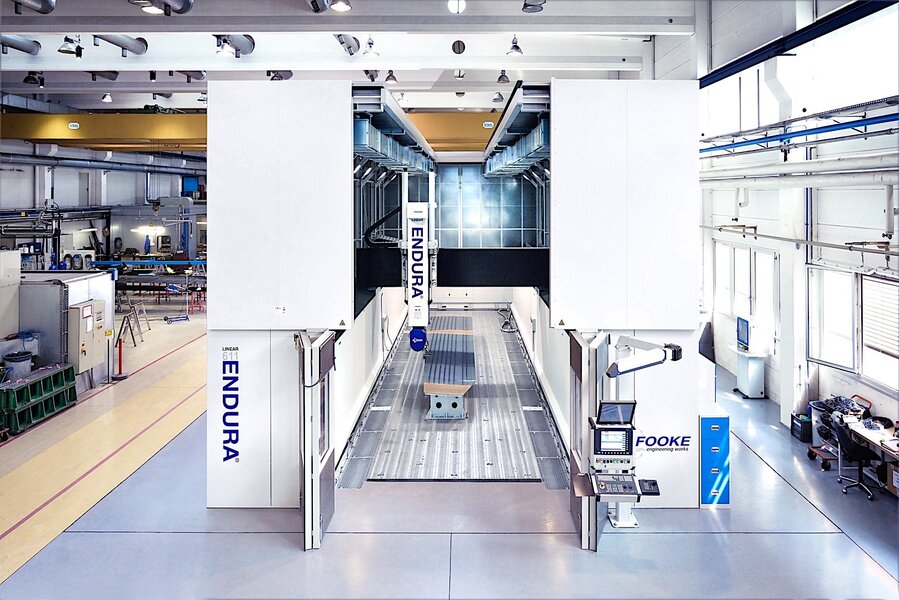

GANTRY MILLING MACHINE

ENDURA® 611LINEAR

For edge trimming, driling and 5-axis machining of CFRP workpieces.

Suction unit for the extraction of chips and dust.

COCKPIT DOORS A350 XWB

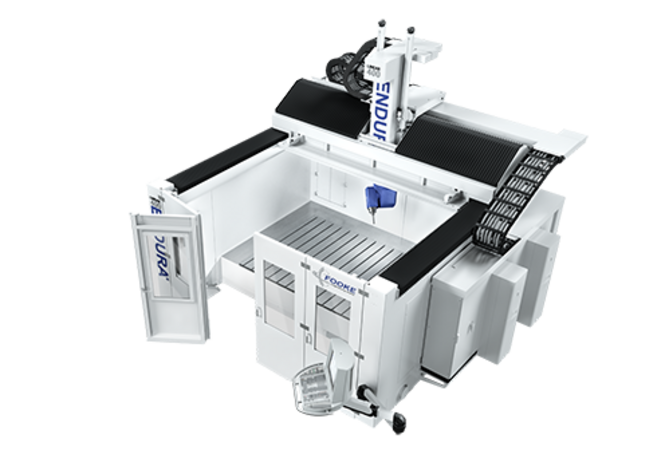

GANTRY MILLING MACHINE ENDURA® 907LINEAR

For milling and tapping workpieces made of CFRP, aluminum and titanium

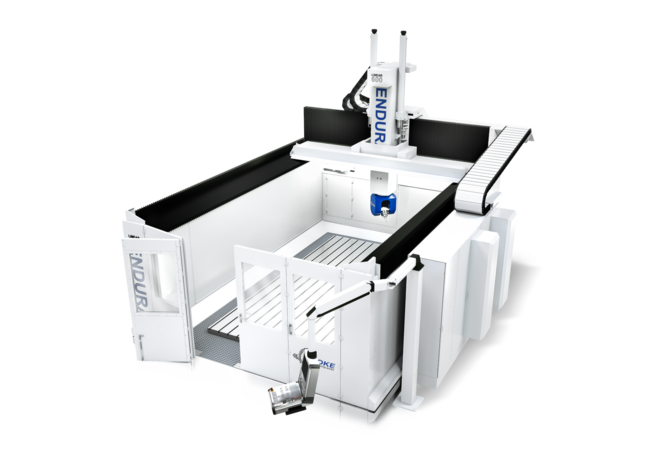

GANTRY MILLING MACHINE

ENDURA® 907LINEAR

For milling and threading/drilling of workpieces made of CFRP, aluminum and titanium.

High-performance milling head extraction incl. explosion protection:

TAILPLANES AND VARIOUS PARTS FOR AIRBUS AIRCRAFTS

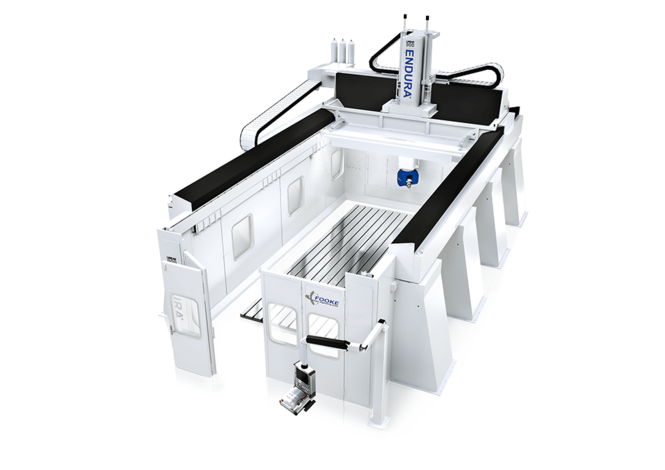

GANTRY MILLING MACHINE

ENDURA® 907LINEAR

For milling, drilling, spindling, cutting and sawing of workpieces made of carbon fiber reinforced plastics.

- Workpiece carrier storage for automatic carrier change.

- High-performance milling head extraction incl. explosion protection

- Full machine enclosure

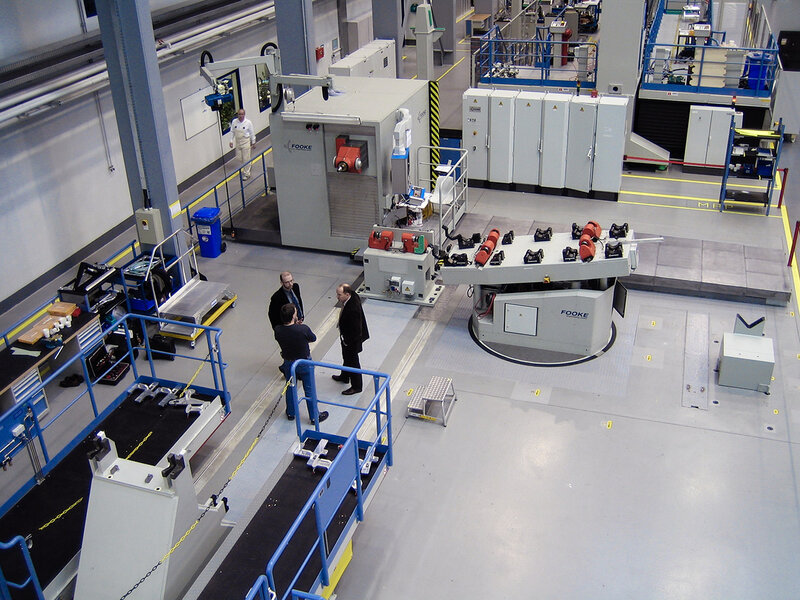

DRILLING STATION WITH CLAMPING DEVICE

Fuselage drilling as well as drilling and spindling of the vertical stabilizer in one system.

- For clamping, aligning and drilling

- Vertical and horizontal machining of the workpiece

- Machining and measuring (QM inspection)

STRINGER PROFILES

FOR SUKHOI SUPERJET 100

TRAVELLING COLUMN MILLING MACHINE

ENDURA® 1005LINEAR

Machining of aluminum profiles with multiflexible clamping device, adjustable in each axis.

Numerous aerospace customers already rely on turnkey solutions from FOOKE

To be a part of it, profound expertise and proficiency in all aerospace standards is a must.

In the aerospace industry each and every gram instantly pays off. With our long-time experience and know-how, we supply state-of-the-art solutions for weight saving and efficient component machining.

LATERAL MILLING MACHINE

ENDURA® 1100LINEAR

LATERAL MILLING MACHINE

ENDURA® 1100LINEAR

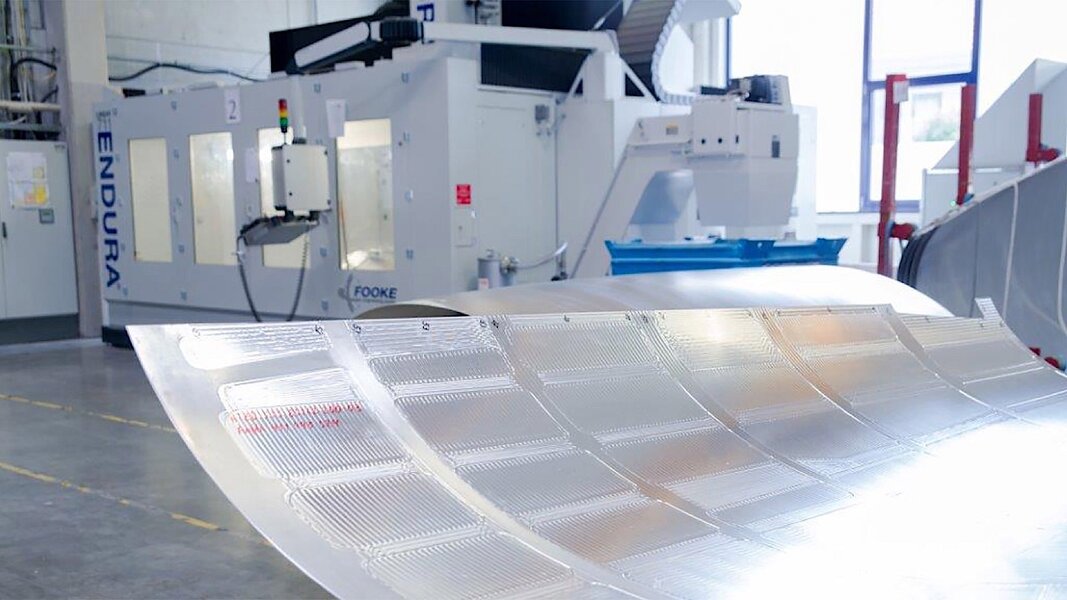

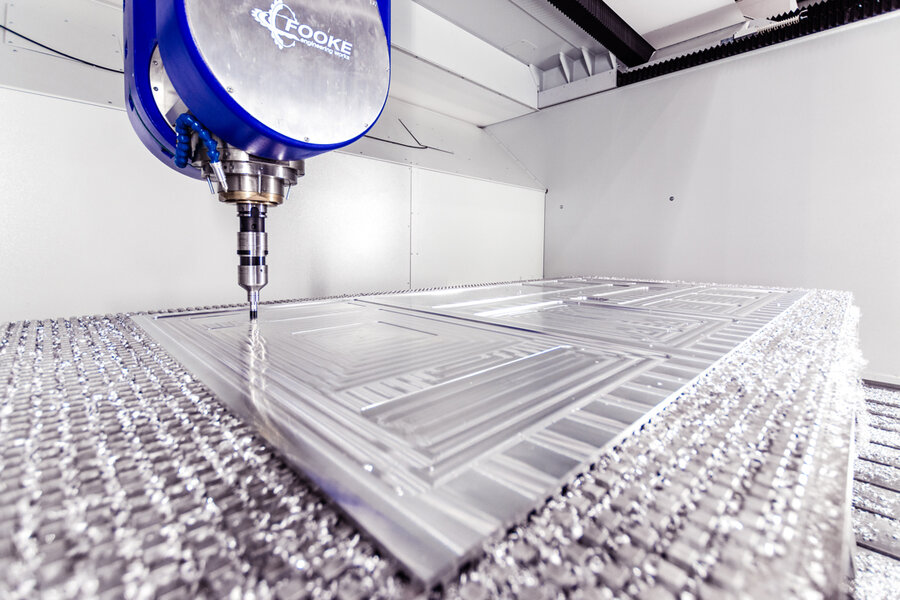

3D SURFACE MILLING OF THIN-WALLED ALUMINUM OUTER SKIN SHEETS

GANTRY MILLING MACHINE

ENDURA® 611LINEAR

Machining of highly complex spherically shaped components and structural parts made of aluminum, carbon fiber and GLARE.

For milling aluminum fuselage segments up to a size of 14,000 x 1,170 x 785 mm

Sheet thickness measurement using ultrasonic probe for high precision milling of aircraft outer skin panels.

Aviation & Aerospace

Take off for new opportunities.

Minimum tolerances and a wide range of modern materials. These are the real challenges of the aerospace industry.

Demanding workpieces require demanding solutions. To provide these, we not only develop the machine required for the machining work, but also workpiece clamping systems specially tailored to the workpiece either as hard tooling systems or universal ‘multi-tooling clamp systems’. We supply turnkey solutions, all from one single source.

The high-performance chipping of aluminium or titanium and the machining of CFRP and other compound materials require different milling machines and machining centres – if desired, including hybrid process technology, such as abrasive water jet cutting or laser cutting and milling combined in one single system.

What makes us proud

Some of our references in the aerospace industry

AIRBUS │ AIRBUS HELICOPTERS │ GKN FOKKER │ HARBIN AIRCRAFT │ HIZE AERO │ JCM │ LO-CAT SYSTEMS │ PILATUS AIRCRAFT │ PREMIUM AEROTEC │ SHANGHAI AIRCRAFT│ SPACE X │…

FOOKE Product Portfolio

ENDURA® 400LINEAR

ENDURA® 600LINEAR

ENDURA® 700LINEAR

ENDURA® 7000LINEAR

ENDURA® 900LINEAR

ENDURA® 900LINEAR COMPACT

ENDURA® 1000LINEAR

ENDURA® PRO LINEAR

FSW Machines

ENDURA® 400LINEAR

Our specialist for plastics machining.

Traverse paths

X-axis: 2,700 mm

Y-axis: 2,000 - 3,000 mm

Z-axis: 1,200 mm

ENDURA® 600LINEAR

High dynamic portal milling machine for universal applications.

Traverse paths

X-axis: 5,000 - 30,000 mm

Y-axis: 2,800 / 3,500 mm

Z-axis: 1,500 / 2,000 mm

ENDURA® 700LINEAR

Compact gantry milling machine with large machining area and small footprint.

Traverse paths

X-axis: 1,500 / 2,200 / 5,500 mm

Y-axis: 2,000 / 2,800 / 3,500 mm

Z-axis: 1,200 / 1,500 mm

ENDURA® 7000LINEAR

For high-performance heavy-duty machining of high-strength materials.

Traverse paths

X-axis: 3,000 / 4,500 / 6,000 mm

Y-axis: 3,500 / 4,000 / 4,500 mm

Z-axis: 1,500 mm

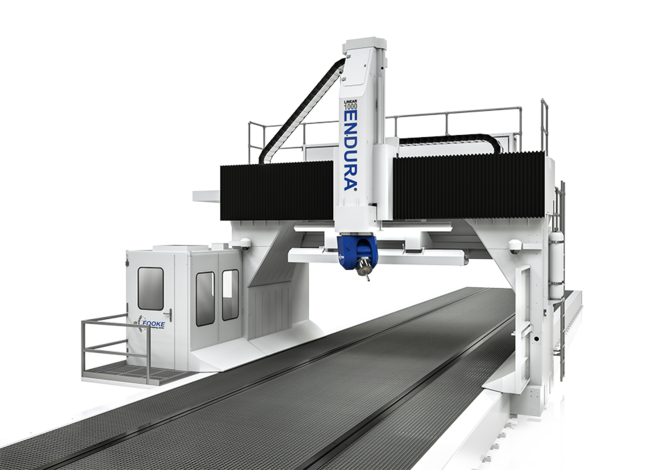

ENDURA® 900LINEAR

High dynamic gantry milling machine for universal applications.

Traverse paths

X-axis: 3,000 - 30,000 mm

Y-axis: 2,000 - 4,000 mm

Z-axis: 1,200 - 3,000 mm

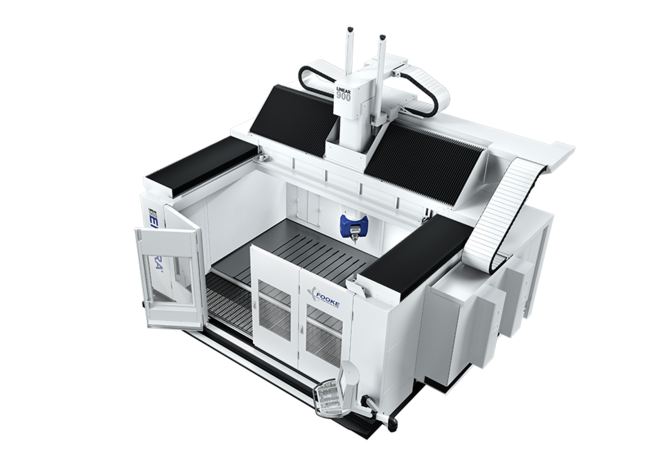

ENDURA® 900LINEAR COMPACT

Compact gantry milling machine with large machining area and small footprint.

Traverse paths

X-axis: 2,500 / 4,000 / 5,500 mm

Y-axis: 3,500 mm

Z-axis: 1,500 mm

ENDURA® 1000LINEAR

Travelling column milling machine for processing large-volume workpieces.

Traverse paths

X-axis: 5,000 - 60,000 mm

Y-axis: 2,000 - 5,000 mm

Z-axis: 800 - 2,000 mm

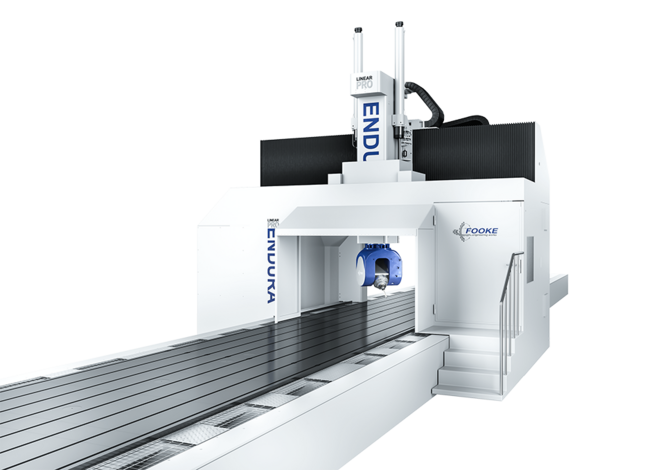

ENDURA® PRO LINEAR

Long bed gantry milling machine for highly dynamic 5-axis machining of long workpieces.

Traverse paths

X-axis: 6,000 - 60,000 mm

Y-axis: 1,600 / 2,400 / 3,500 mm

Z-axis: 1,100 / 1,500 mm

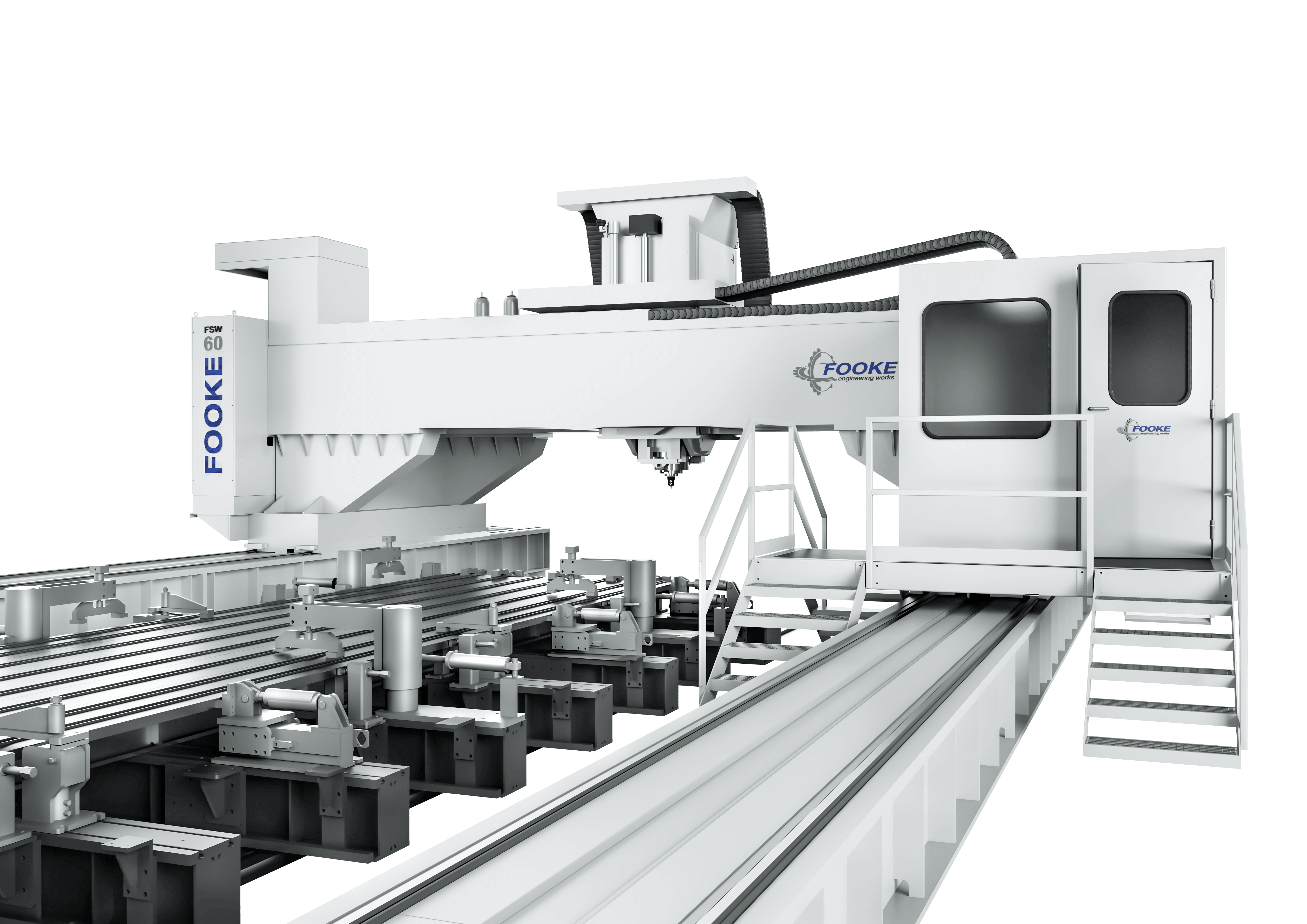

FSW Machines

Friction stir welding machines from FOOKE

Profitable FSW solutions for your production proces.

Do you have questions about our products.

Our sales team is at your service!

Feel free to mail us or call us. We look forward to your questions and suggestions. You will receive an answer as soon as possible.

Tel.: +49 (0) 2861 / 8009 - 222

E-Mail: sales@fooke.de