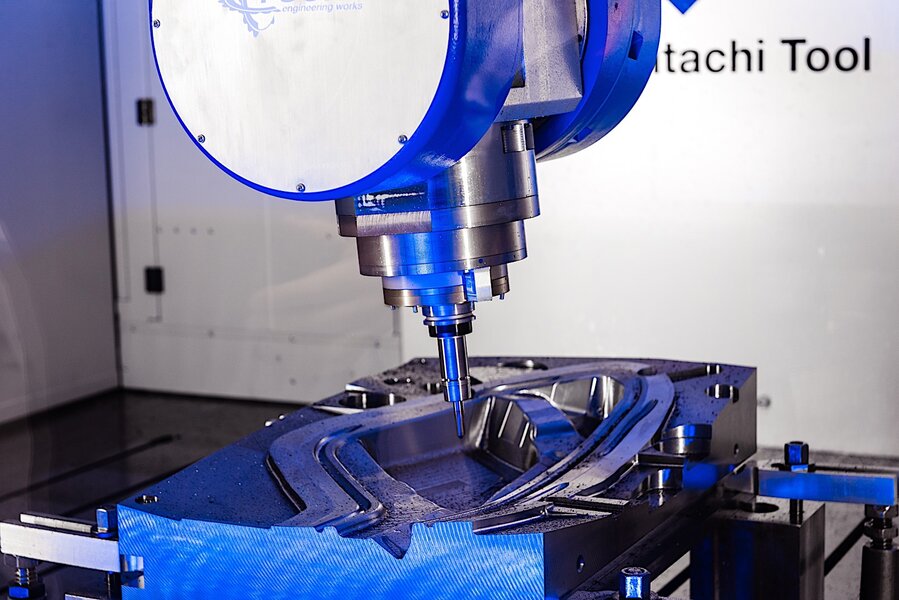

40% INCREASE IN MILLING PROCESS PRODUCTIVITY:

Full machining - roughing and finishing: 73 hours → 47 hours.

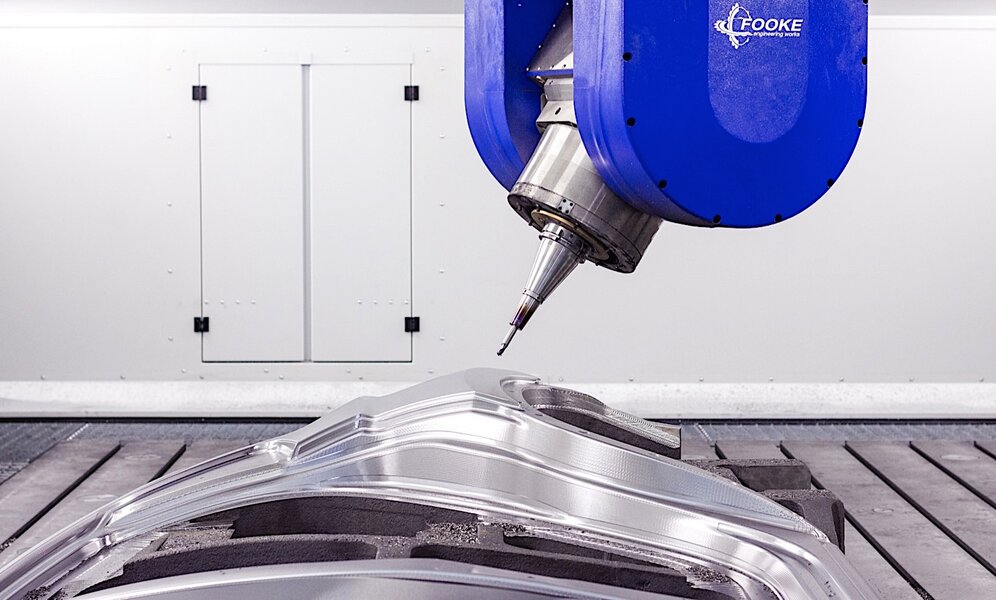

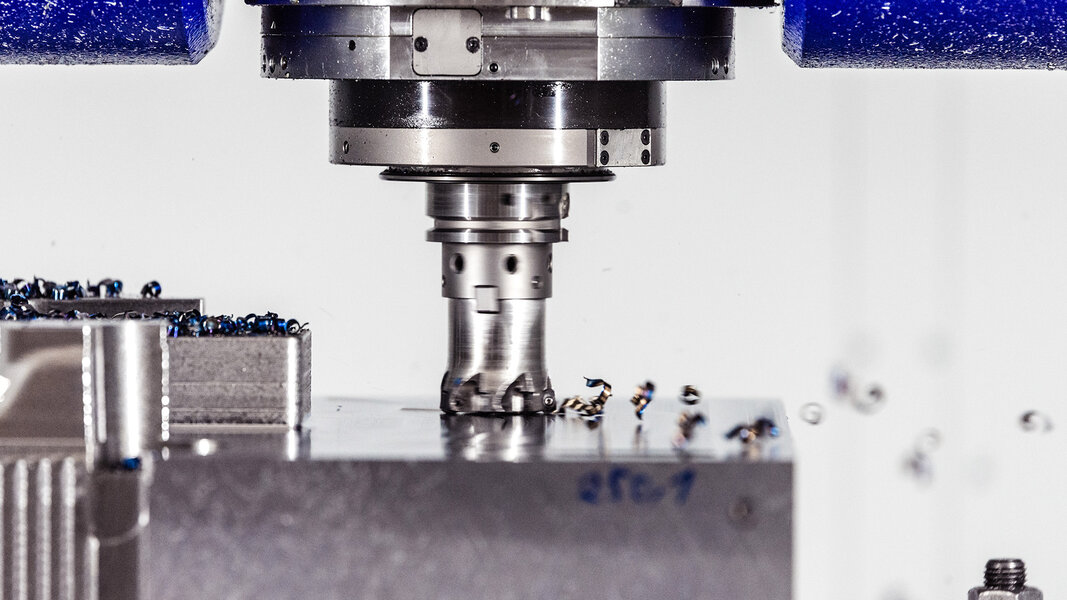

Highest accuracies and maximum surface quality

TOOL AND MOLD CONSTRUCTION. PROSPECT MOLD and FOOKE

"Compared to other milling machines we use, FOOKE machines are characterized by consistent, optimum geometric accuracy and the lowest percentage of unscheduled machine downtime. Even after more than 10 years of cooperation, FOOKE continues to convince and inspire us time and again."

Brandon Wenzlik, Prospect Mold

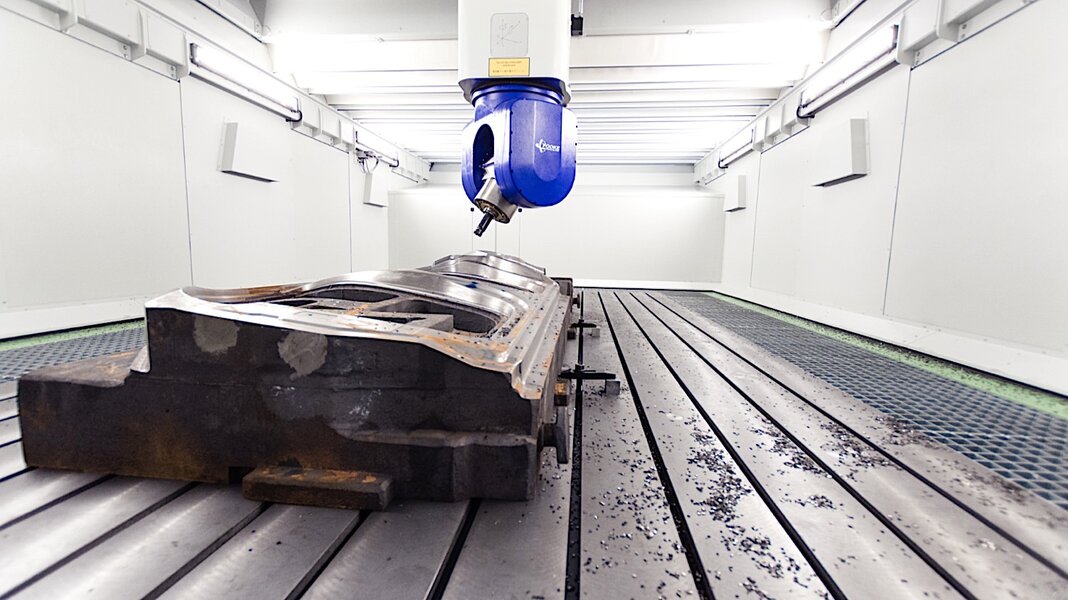

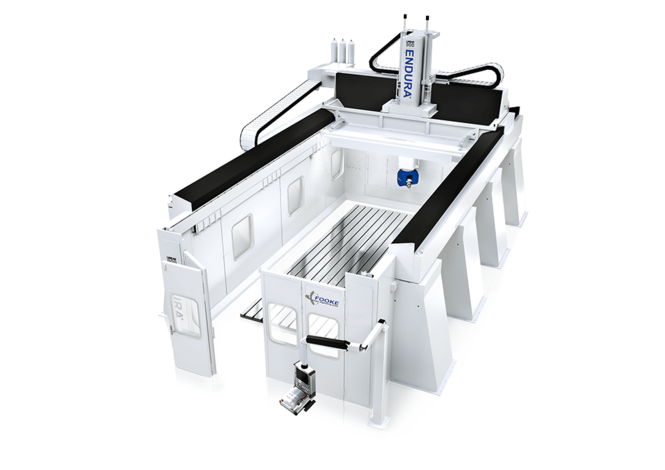

COMPACT GANTRY MILLING MACHINE

ENDURA® 7012LINEAR

Specially designed for high-performance heavy-duty machining of solid and high-strength materials.

HIGHLY accurate for today's required tolerances in tool making, from roughing to long finishing processes.

MODEL CONSTRUCTION. SIEBENWURST and FOOKE

"The positive and solution-oriented attitude of all FOOKE employees involved in the project convinced us. FOOKE products stand for excellent processing quality Made in Germany. The planning reliability and the very high-quality assurance give us a clear advantage over our competitors."

Stephan Dunke

Team Leader Manufacturing/ CAM MB Model construction

www.siebenwurst.com

VEHICLE DESIGN

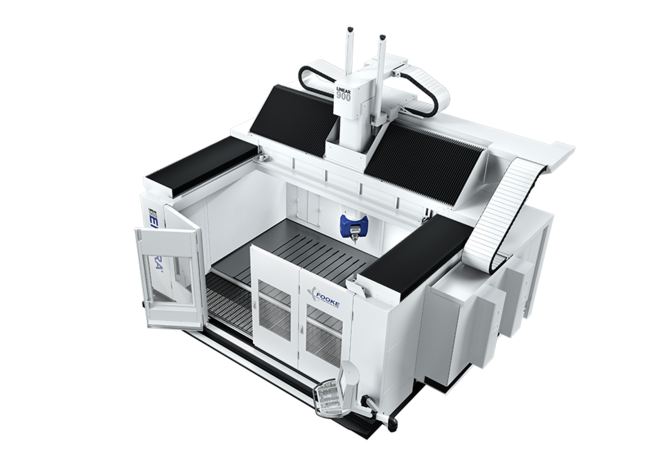

GANTRY MILLING MACHINE

ENDURA® 611LINEAR

Excellent surface qualities with highly dynamic 5-sided machining of large 1:1 design models.

BMW I8 – Aluminum, milled to a piece of art.

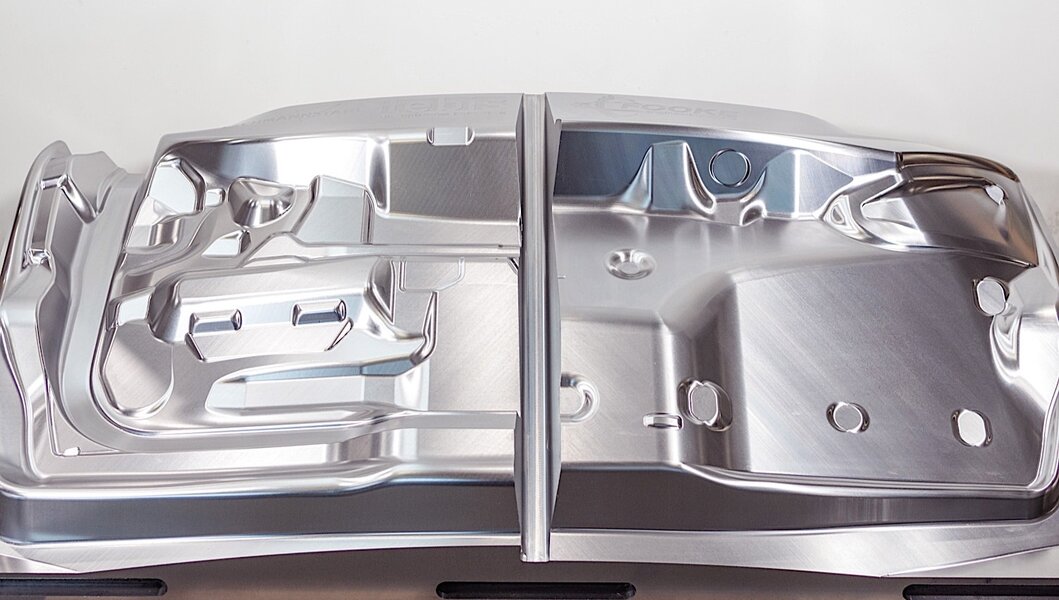

Excellent surface qualities in model and mold making

MOLD CONSTRUCTION. AMARI and Fooke

"The performance parameters of the FOOKE machines convinced us. Because they fit our requirements perfectly. We came across Fooke through a recommendation from one of our customers. In the meantime, we have enough experience ourselves to be able to say: Fooke stands for competence, reliability and excellent machine service."

Josef Reiter, CEO

RIM MOLD

MODEL AND MOLD CONSTRUCTION

Reduction of processing time thought FOOKE milling strategies matched to the highly dynamic ENDURA® machine system.

FORMING TOOL - SIDE PART – CASTING

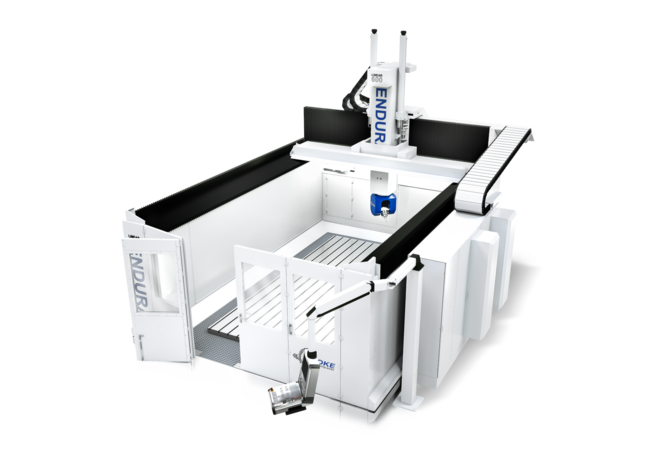

GANTRY MILLING MACHINE

ENDURA® 908LINEAR

Excellent surface qualities.

VEHICLE DESIGN

GANTRY MILLING MACHINE

ENDURA® 904LINEAR

Highly dynamic machining of 1:1 design models.

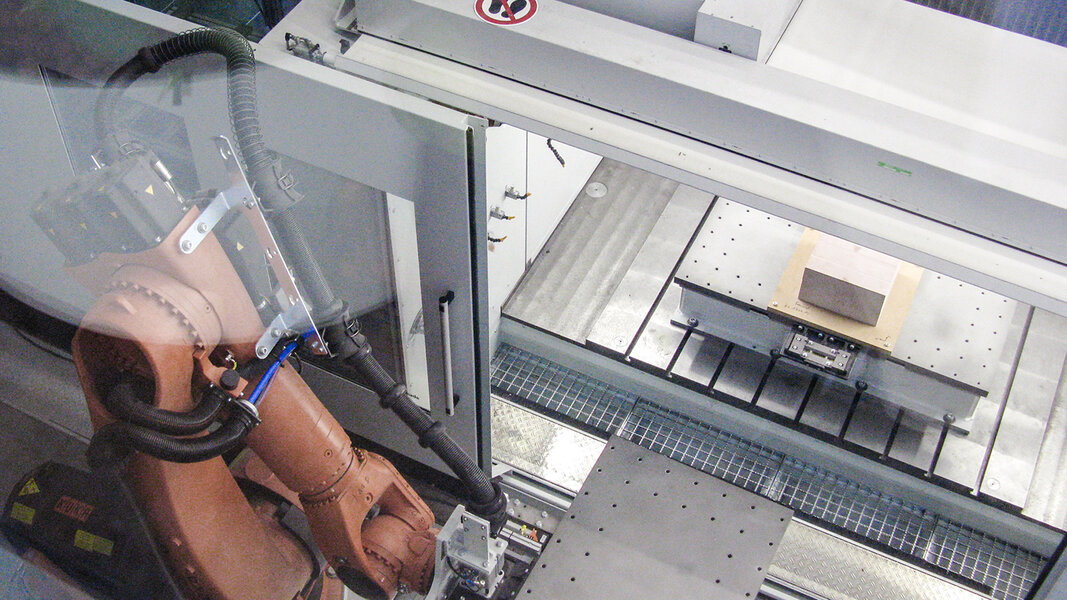

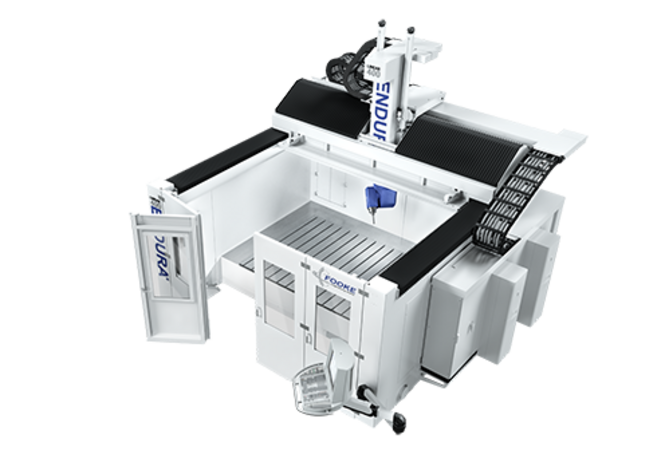

COMPACT GANTRY MILLING MACHINE

ENDURA® 711LINEAR

With robot system for automatic loading and unloading.

COMPACT GANTRY MILLING MACHINE

ENDURA® 704LINEAR

Optimum accessibility: 5-sided machining of the function side in one clamping.

GANTRY MILLING MACHINE

ENDURA® 905LINEAR

Cubing models for function testing, pilot series or exclusive small series.

TOOL AND MOLD CONSTUCTION

COMPACT GANTRY MILLING MACHINE ENDURA® 704LINEAR

Highly dynamic finishing and high precision rest machining.

TOOL AND DIE. CDM Tool & Manufacturing and FOOKE

"With the decision for a milling machine from FOOKE we have brought new momentum to our process. Less set-up time means more machining time. This enables us to carry out customer orders more economically and productively".

Mike Balderas, New Business & Marketing Manager

TAILGATE – INTERIOR & EXTERIOR

COMPACT GANTRY MILLING MACHINE ENDURA® 7012LINEAR

Versatile machine parameter settings and the optimum machine dynamics adapted to your machining task.

Automotive

Different times, different requirements

What used to be only possible through great manual skill, is now done to perfection by modern machine tools.

Surface quality and precision - these are the requirements of model, prototype and tool and mold making. Different materials, from rigid foam to alloyed tool steel, must be machined efficiently and reliably on one machine. FOOKE offers high-performance, highly dynamic 5-axis milling machines for this purpose.

Models and prototypes in particular, but also tools and molds, are now machined linearly with the narrowest path distances. Partly in the classic 3+2 operation and increasingly also 5-axis simultaneous. In this type of machining, the programmed feed rate must be kept almost constant and at the same time at the highest level. Maximum rigidity of the machine structure elements and the feed drives are the basis for the best surface qualities and accuracies with outstanding productivity.

What makes us proud

Some of our references in Vehicle design

Prototyping - Model and mold construction - Tool construction - Jig and gauge making - Cubing

ALFA ROMEO F1 │ AUDI │ ASTON MARTIN F1 │ BMW │ BERTRANDT │DAIMLER │ EDAG │ FORD │ FRIMO │ HONDA │ KRAUSSMAFFEI TECHNOLGY │ MERCEDES-BENZ │ MERCEDES BENZ FORMULA 1 │ PORSCHE │RED BULL RACING │ SAIC VOLKSWAGEN AUTOMOTIVE │ SALZGITTER AUTOMOTIVE ENGINEERING │ SAUBER GROUP │ SCHÄFER │ SIEBENWURST │SILBERFORM │ TOYOTA │ VOLKE │ VOLKSWAGEN │…

FOOKE Product Portfolio

ENDURA® 400LINEAR

ENDURA® 600LINEAR

ENDURA® 700LINEAR

ENDURA® 7000LINEAR

ENDURA® 900LINEAR

ENDURA® 900LINEAR COMPACT

FSW Machines

ENDURA® 400LINEAR

Our specialist for plastics machining.

Traverse paths

X-axis: 2,700 mm

Y-axis: 2,000 - 3,000 mm

Z-axis: 1,200 mm

ENDURA® 600LINEAR

High dynamic portal milling machine for universal applications.

Traverse paths

X-axis: 5,000 - 30,000 mm

Y-axis: 2,800 / 3,500 mm

Z-axis: 1,500 / 2,000 mm

ENDURA® 700LINEAR

Compact gantry milling machine with large machining area and small footprint.

Traverse paths

X-axis: 1,500 / 2,200 / 5,500 mm

Y-axis: 2,000 / 2,800 / 3,500 mm

Z-axis: 1,200 / 1,500 mm

ENDURA® 7000LINEAR

For high-performance heavy-duty machining of high-strength materials.

Traverse paths

X-axis: 3,000 / 4,500 / 6,000 mm

Y-axis: 3,500 / 4,000 / 4,500 mm

Z-axis: 1,500 mm

ENDURA® 900LINEAR

High dynamic gantry milling machine for universal applications.

Traverse paths

X-axis: 3,000 - 30,000 mm

Y-axis: 2,000 - 4,000 mm

Z-axis: 1,200 - 3,000 mm

ENDURA® 900LINEAR COMPACT

Compact gantry milling machine with large machining area and small footprint.

Traverse paths

X-axis: 2,500 / 4,000 / 5,500 mm

Y-axis: 3,500 mm

Z-axis: 1,500 mm

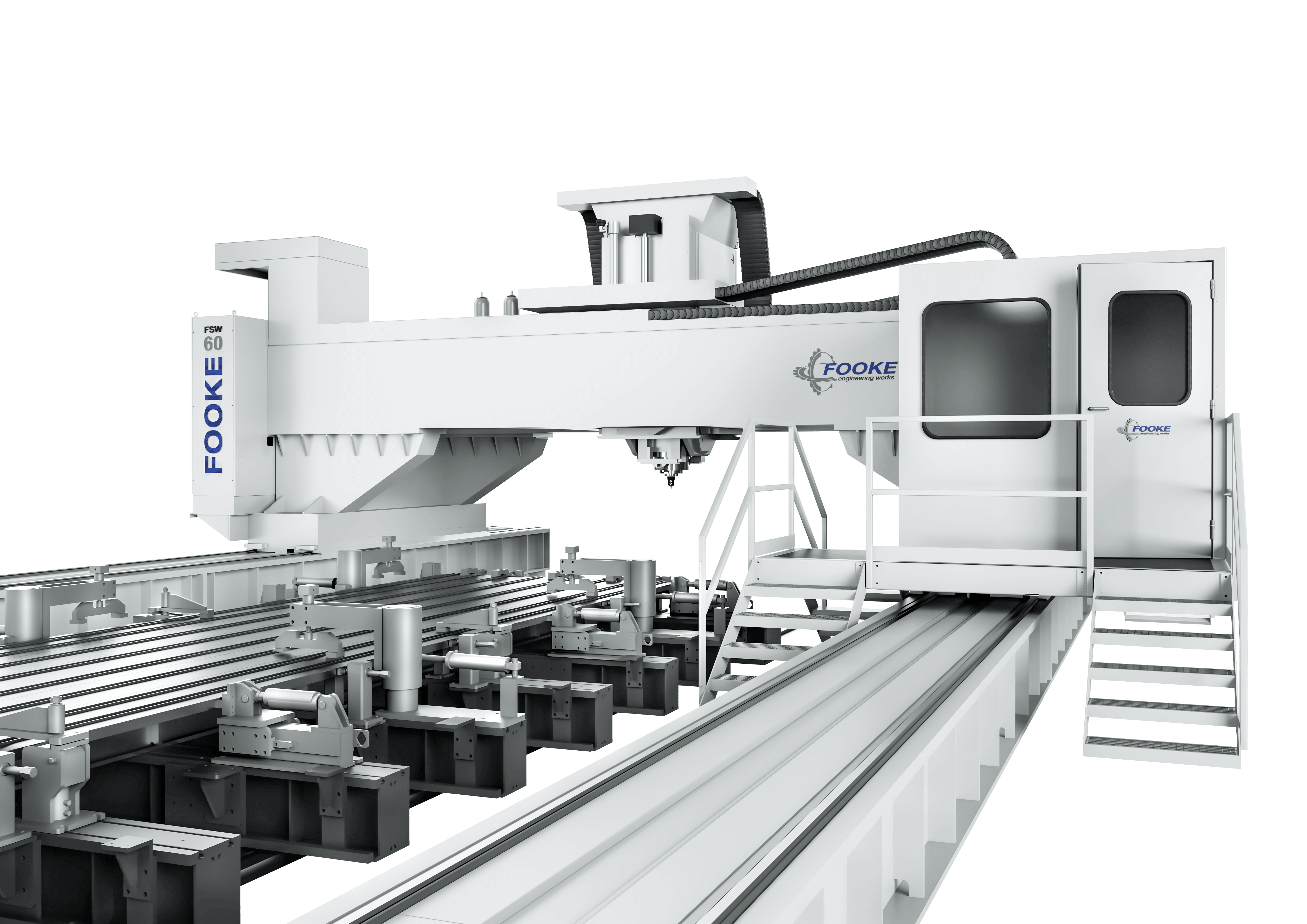

FSW Machines

Friction stir welding machines from FOOKE

Profitable FSW solutions for your production proces.

Do you have questions about our products

Our sales team is at your service

Feel free to mail us or call us. We look forward to your questions and suggestions. You will receive an answer as soon as possible.

Tel.: +49 (0) 2861 / 8009 - 222

E-Mail: sales@fooke.de