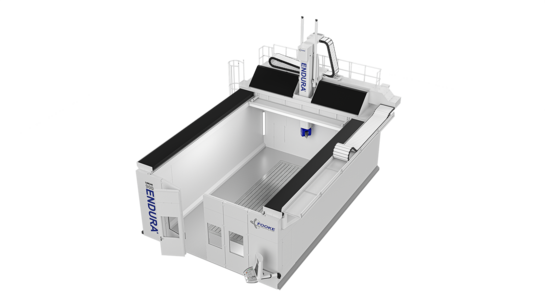

Gantry Milling Machine

Highly dynamic CNC milling machine for universal applications.

The latest generation in ENDURA® gantry milling machines has been designed with an overhead travel portal and is based on already extremely successful conventional ENDURA® products. The use of linear drive motors in our 5-axis milling machines eliminates the need for many mechanical elements such as gears, bearings, ball screws and rack gears, thereby enhancing

structural rigidity, reliability and precision in particular. Modular and fast.

Acceleration rates of up to 5 m/s², closed loop system reinforcements of 5 m/(min x mm) and a maximum deviation of 0.015 mm impressively reflect the power and precision of this 5-axis milling machine.

Up to 50% speed increase over conventional gantry milling machines, while ensuring highest levels of surface quality and accuracy. The Kv factor of 5-7 m/(min x mm) is a clear indicator for the machine's productivity; with conventional drive technology, the Kv factor is generally approximately 1-3 m/(min x mm).

Advantages at a glance.

- Highly dynamic, for universal applications

- Direct drives in all axes (linear and torque motors)

- Excellent structural rigidity, highest dynamics and accuracies

- Very large enveloped machining area

- Market leader in 1:1 machining in German automotive design

- Perfectly matched machine concept for productive end-to-end machining from aluminum to steel

- Now also available in compact design

- Travels up to 30,000 x 4,000 x 3,000 mm

- Range of materials: plastic, CFRP/GFRP, modeling block material, aluminum, cast iron, steel

Gantry Milling Machine

ENDURA 900LINEAR

Highly dynamic gantry milling machine for universal applications.

Traverse paths

X-axis: 3,000 - 30,000 mm

Y-axis: 3,000 / 3,500 / 4,000 /4,500 mm

Z-axis: 1,500 / 2,100 / 2,500 / 3,000 mm

Feed rates

X-axis: 5 - 65,000 mm/min

Y-axis: 5 - 65,000 mm/min

Z-axis: 5 - 65,000 mm/min

Acceleration up to 5 m/sec²

Position accuracy

X-axis: 0.025 mm

Y-axis: 0.020 mm

Z-axis: 0.015 mm

Position scatter

X-axis: 0.010 mm

Y-axis: 0.010 mm

Z-axis: 0.010 mm

Modular and extremely rigid machine with an intelligent hybrid design (steel, welded, cast iron and mineral casting components).

Wear-free, highly dynamic linear motors in all linear axes (X, Y and Z).

Direct measuring systems in all axes (X, Y, Z, A and C).

Safety system and brakes in all linear axes (X, Y and Z).

Drive units efficiently protected by bellows.

Machine room accessible at ground level, loadable by crane or forklift.

Automatic tool changing systems

Minimum quantity spray dosing system

Coolant systems (wet operation)

Tool measuring systems

Workpiece measuring systems

Chips and dust disposal systems

Workpiece clamping systems

Plane cover / Sound insulation enclosure

Online-Service

Market leader in 1:1 machining in German automotive design

Features, technology and equipment:

- Highly dynamic overhead GANTRY tool milling machine:

Portal moving in X-direction. - Design of the machine:

Side walls (X-axis) in pylon column design with raised beds (welded steel structures, filled with highly damping special concrete), portal (Y-axis), cross slide and walking beam (Z-axis) as extremely rigid, yet weight-optimized welded steel construction. - Drive technology of linear axes:

Water-cooled linear motors in the linear axes (X, Y and Z), X-axis design as GANTRY axes pair.

- Direct measuring systems:

All linear and rotary axes are equipped with direct measuring systems. - Z-axis weight compensation :

The drive of the Z-axis is supported by two highly dynamic hydraulic cylinders. - Safety system of linear axes:

The linear axes are equipped with a safety system that can brake and safely hold the axes in case of voltage loss. - Linear axes guides:

The linear axes are equipped with hardened and ground, backlash-free pre-tensioned guide elements.

Download Product brochure

Download Milling Head Overview