Profile Milling Machine

Longbed milling machine - our specialist for stringer and profile machining with cutting rates of up to 11.0 l/min.

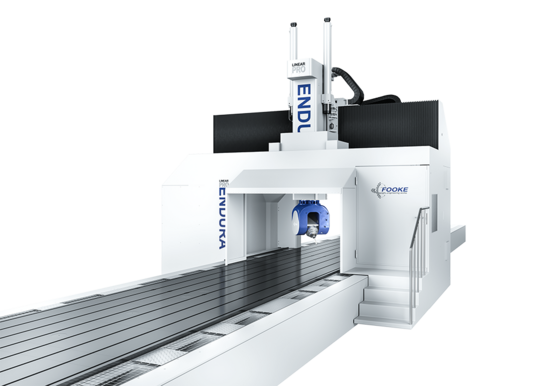

The ENDURA® PRO LINEAR is a 5-axis gantry – Longbed milling machine, especially designed for high-performance cutting of aluminum and composites profile structure elements. Its monoblock machine bed construction ensures a uniform load distribution. Long traverse paths in X, Y and Z and the application of a highly rigid fork milling head,

enable an efficient 5-axes processing of large volume, spatially curved and twisted workpieces, e.g. stringer and other structural components from the aviation industry. The highly rigid construction of the structural and feed drives components results in highest dynamics as well as excellent accuracy

of positioning and repeatability in the entire machining area.

The milling process of this 5-axis long bed profile milling machine is absolutely stable. Consequently, highest cutting rates up to 11.0 l/min are achieved with minimal wear of the milling cutting edge.

Advantages at a glance.

- Specialist for stringer and profil machining

- Highly dynamic 5-axis machining of long workpieces

- Material removal rates up to 11.0 l/min

- Flexible workpiece clamping systems

- Ergonomic loading

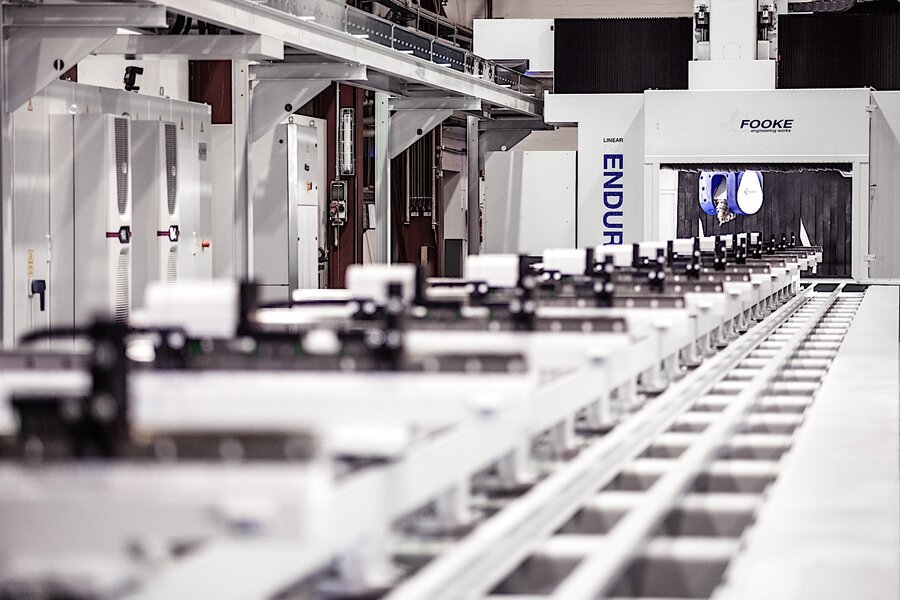

- Two-station component machining for process-parallel loading

- Monobloc machine bed design, modularly expandable

- Encapsulated machining area by bullet-proof lamellas

- Travels up to 60,000 x 3,500 x 1,500 mm

- Range of materials: aluminum, composites (CFRP/GFRP)

Long Bed Milling Machine

ENDURA® PRO LINEAR

Long bed milling machine for the high-dynamic 5-axis machining of long workpieces.

Traverse paths

X-axis: 6,000 - 60,000 mm

Y-axis: 1,600 / 2,400 / 3,100 mm

Z-axis: 1,100 / 1,500 mm

Feed rates

X-axis: 5 - 60,000 mm/min

Y-axis: 5 - 65,000 mm/min

Z-axis: 5 - 65,000 mm/min

Acceleration up to 3.5 m/sec²

Position accuracy

X-axis: 0.030 mm

Y-axis: 0.020 mm

Z-axis: 0.015 mm

Position scatter

X-axis: 0.015 mm

Y-axis: 0.010 mm

Z-axis: 0.010 mm

Long-bed milling machine in gantry construction

Inherently rigid machine table construction in monoblock design

Certified impact resistant vertical blinds

Optimal chip conveyance solution

Wear free, high dynamic linear motors and direct measuring systems in Y- and A-axis

Wear free, high dynamic torque motors and direct measuring systems in C- and A-axis

Automatic tool changing systems

Minimum quantity spray dosing system

Tool measuring systems

Workpiece measuring systems

Chips and dust disposal systems

Safety systems for free accessibility

Video monitoring of machine interior

Various tool clamping applications

Intelligent workpiece clamping solutions

Online Service

Material removal rates of up to 11 l/min

Encapsulated machining area

Features, technology and equipment:

- Highly dynamic GANTRY portal milling machine:

Portal moving in X-direction. - Design of the machine:

Machine bed (X-axis) made of a solid monoblock casting, cross slide, portal (Y-axis) and side walls as welded steel construction, walking beam (Z-axis) made of cast iron. - No foundation necessary:

Due to the self-supporting machine bed, a standard industrial floor (reinforced with steel), approx. 400 mm thick, is sufficient for the assembly of the machine. A special foundation is not necessary. The machine is set up and aligned by means of fixations which are bolted down to the floor. - Drive technology of linear axes:

Water-cooled linear motors in linear axes Y and Z, X-axis designed as rack-and-pinion GANTRY drive and drive unit motors in MASTER-SLAVE arrangement.

- Direct measuring systems:

- The X axis is equipped with indirect measuring system, the Y, Z and round axis are equipped with direct measuring systems.

- Z-axis weight compensation:

Two highly dynamic pneumatic cylinder support the drive of the Z-axis. - Safety system of linear axes:

The linear axes are equipped with a safety system that can brake and safely hold the axes in case of voltage loss. - Linear axes guides:

The linear axes are equipped with hardened and ground, backlash-free pre-tensioned guide elements.

Download Product Brochure

Download Milling Head Overview