Stock Machines

We regularly manufacture 5-axis milling machines even without a specific order, which enables attractive delivery times. Here you will find a small selection of available stock machines.

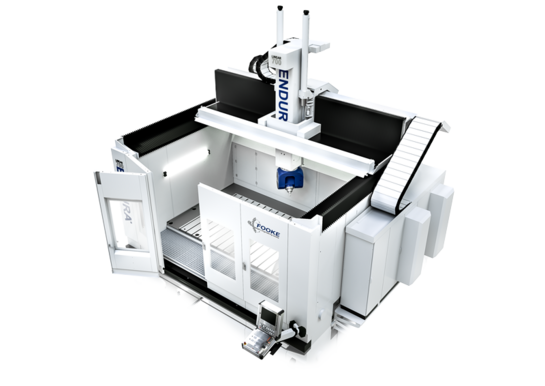

Compact Gantry Milling Machine ENDURA® 410LINEAR

Ultra-modern linear motor milling machine in compact GANTRY design with 5 CNC controlled simultaneous axes, especially suitable for the efficient finish-machining from 5 sides of workpieces made of plastic materials, block materials and aluminium.

X= 2,700 mm x Y= 3,000 mm x Z= 1,200 mm

X= 106.29 Inch x Y= 118.11 Inch x Z= 47.24 Inch

Equipment:

- Milling head 10 with CNC controlled A- und C-axis

- High-frequency milling spindle, HSK63A, 24 kW, 21,000 rpm, 39 Nm / 32.16 HP kW, 21,000 rpm, 28.8 ft-lb

- Machine table / Clamping plate

- CNC-control HEIDENHAIN TNC 640

- Automatic tool changer 50-pockets, HSK63A

- Radio workpiece measuring system

- Laser tool control system

- Display indication for vibration

- Disposal of Chips

- Dust Removal (Prearrangement)

- Plane cover

- Linear Motors in all Axes

Delivery in august 2024!

Compact Gantry Milling Machine ENDURA® 715LINEAR

Ultra-modern linear motor milling machine in compact GANTRY design with 5 CNC controlled simultaneous axes, especially suitable for the efficient finish-machining from 5 sides of workpieces made of plastic materials, block materials and aluminium as well as for smoothing of cast and steel materials.

X= 2,200 mm x Y= 3,500 mm x Z= 1,500 mm

X= 86.61 Inch x Y= 137.79 Inch x Z= 59.05 Inch

Equipment:

- Milling head 15 with CNC controlled A- und C-axis

- High-frequency milling spindle, HSK63A, 45 kW, 20,000 rpm, 130 Nm / 60.3 HP, 20,000 rpm, 95.9 ft-lb

- Machine table / Clamping plate

- CNC-control HEIDENHAIN TNC 640

- Automatic tool changer 68-pockets, HSK63A

- Radio workpiece measuring system

- Laser tool control system

- Chip conveyor

- Emulsion mist extraction

- CLS and MQL

- Plane cover

- Linear Motors in all Axes

Delivery in august 2024!