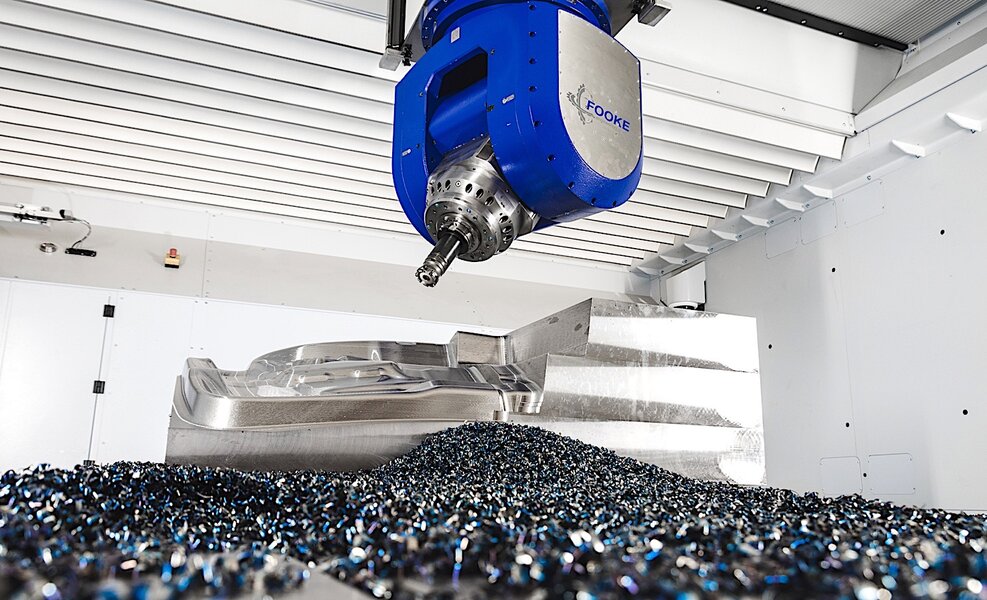

Working together with our partners TEBIS and Eschmann we demonstrate with project „Tailgate“ how highly efficient chipping is implemented in tool construction (material: 1.2379).

Our ENDURA® 7000LINEAR offers the highest dynamics available in the 3D-processing sector for 3 axis-processing as well as in 5 axis- simultaneous chipping.

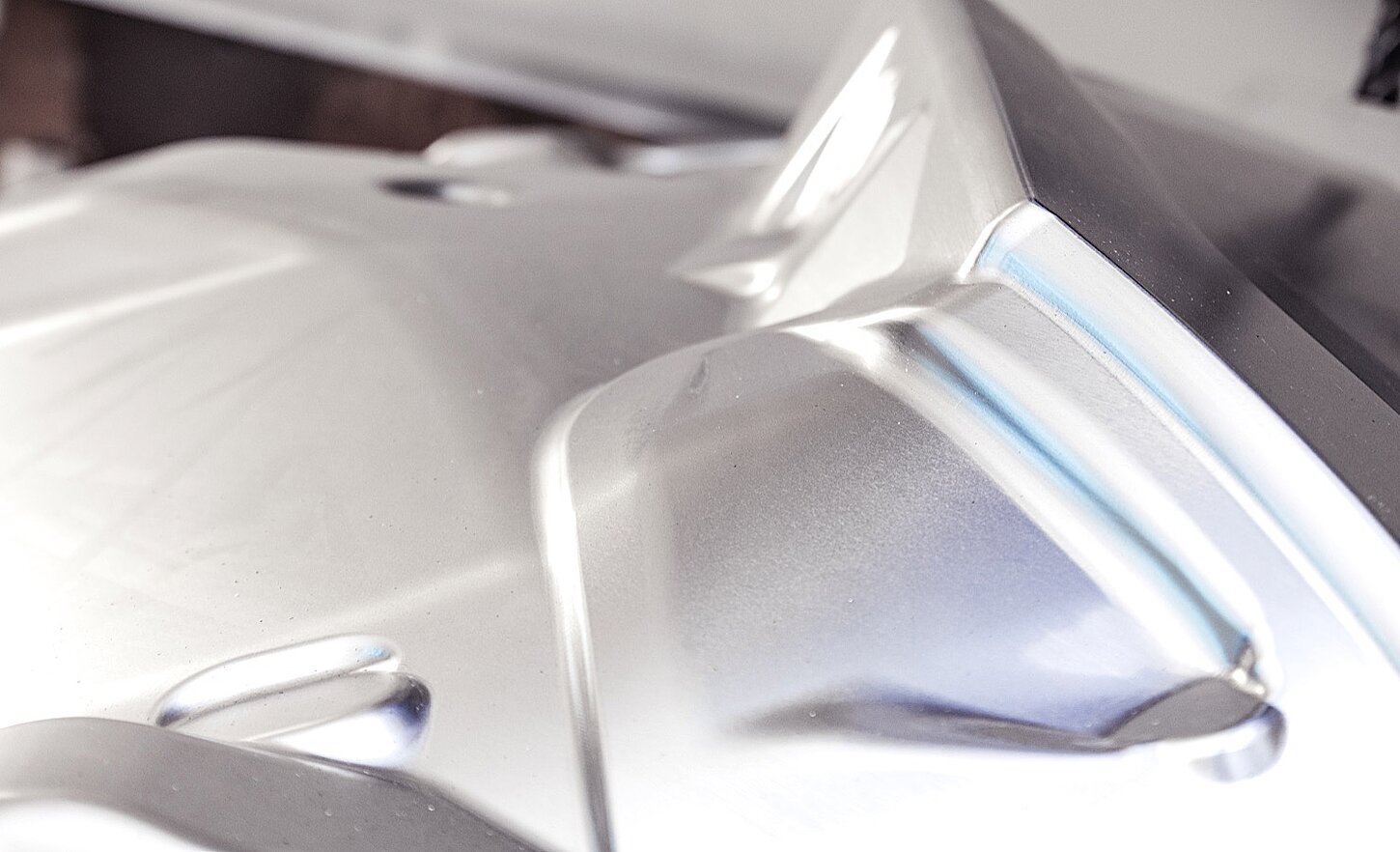

TOOLS Tailgate outer skin

Ball cutter D16 – Vf 5.000 mm/min – ae 0,35 mm (oscillating)

Ball cutter D10 – Vf 3.800 mm/min – ae 0,28mm

Ball cutter C06 – Vf 3.700 mm/min – ae 0,21mm

Total processing time: 7:35 Hrs:Min

TOOLS Tailgate inner panel

Ball cutter D16 – Vf 5.000 mm/min – ae 0,25mm (synchronization only)

Ball cutter D10 – Vf 3.800 mm/min – ae 0,2mm

Total processing time: 10:20 Hrs:Min